Home> Company News> Unlocking Efficiency: The Impact of 6014 Deep Groove Ball Bearing in European Applications

- AddressNo.7001. XUEYUAN ROAD, NANSHAN DISTRICT,SHENZHEN,CHINA

- Factory AddressNo.7001. XUEYUAN ROAD, NANSHAN DISTRICT,SHENZHEN,CHINA

- Worktime9:00-18:00

- Phone(Working Time)0531-85064681

- Phone(Nonworking Time)0531-85064680

- Fax0531-85064680

Unlocking Efficiency: The Impact of 6014 Deep Groove Ball Bearing in European Applications

NOVEMBER 02, 20221 Introduction

In the vast landscape of industrial machinery and equipment, bearings play a pivotal role, serving as the unsung heroes that enable smooth operation and efficiency. Among the myriad types of bearings, the 6014 deep groove ball bearing stands out as a cornerstone component renowned for its versatility and reliability.

The 6014 deep groove ball bearing embodies precision engineering, designed to withstand heavy loads and operate seamlessly in diverse environments. Its introduction revolutionized the way machinery functions, offering a robust solution to the challenges posed by friction and wear.

Through this investigation, we endeavor to shed light on how these bearings have become indispensable assets, elevating operational standards and paving the path towards enhanced efficiency in European applications.

In mechanical engineering applications, selecting the right brand of bearings is crucial for ensuring optimal performance and reliability.

|

Brand |

Features |

Benefits |

Drawbacks |

|

SKF |

High-quality steel construction |

Excellent load-carrying capacity |

Relatively higher cost |

|

NSK |

Precision engineering for smooth operation |

Long service life |

Limited availability in some regions |

|

FAG |

Advanced sealing technology for contamination resistance |

Suitable for harsh environments |

Premium pricing |

|

NTN |

Wide range of applications |

Cost-effective option |

May require frequent maintenance |

|

Timken |

Superior durability and reliability |

Trusted brand in the industry |

Higher initial investment |

In conclusion, the choice of 6014 bearing brands is a critical decision that can significantly impact machinery performance and reliability. Each brand brings its own unique history, expertise, and innovations to the table, offering a diverse range of solutions to meet the needs of various industries. Whether it's SKF's pioneering research, NSK's precision engineering, FAG's advanced sealing technology, NTN's cost-effective solutions, or Timken's durability and reliability, industries have a plethora of options to choose from when it comes to 6014 bearings.

2 Understanding 6014 Deep Groove Ball Bearings

Deep groove ball bearings represent a fundamental pillar in the world of mechanical engineering, offering unparalleled versatility and efficiency. Among these, the 6014 deep groove ball bearing emerges as a stalwart component, revered for its remarkable attributes and wide-ranging applicability in European industries.

Definition and Basic Characteristics:

A deep groove ball bearing is a type of rolling-element bearing characterized by its deep raceway grooves, enabling it to accommodate both radial and axial loads with ease. This design facilitates smooth operation at high speeds while maintaining low friction levels, making it an ideal choice for various applications.

The 6014 deep groove ball bearing adheres to these principles with precision, featuring a robust construction that ensures optimal performance even in demanding environments. Its deep grooves provide ample space for the balls to move freely, distributing loads evenly and minimizing wear over time.

Detailed Specifications:

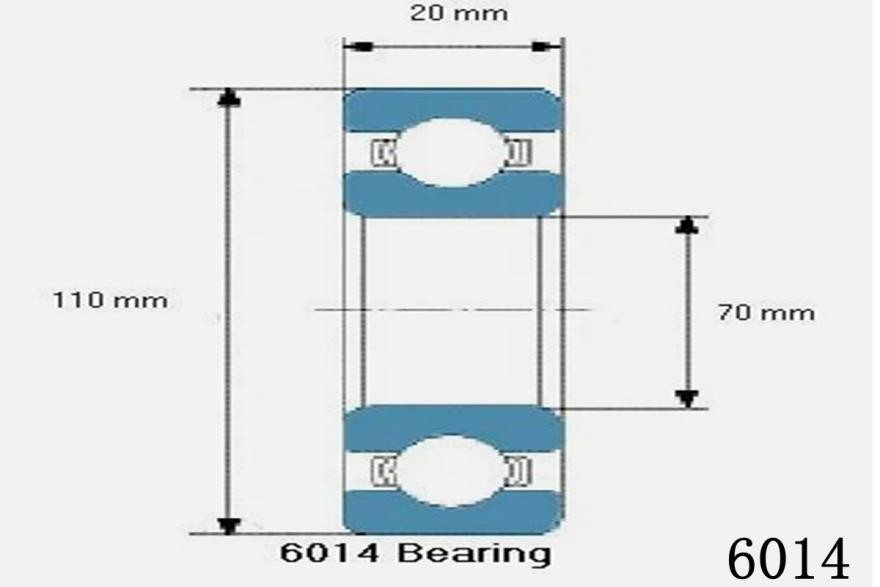

When delving into the specifics of the 6014 bearing, one encounters a meticulously crafted component designed to meet the stringent requirements of European applications. With a bore diameter of 70mm, an outer diameter of 110mm, and a width of 20mm, the 6014 bearing offers ample capacity to support heavy loads while maintaining structural integrity.

Constructed from high-quality materials such as chrome steel or stainless steel, the 6014 bearing exhibits exceptional durability and corrosion resistance, ensuring longevity even in harsh operating conditions. Additionally, advanced manufacturing techniques further enhance its performance, allowing for smoother rotation and reduced noise levels.

Comparison with Other Bearings:

In the realm of European applications, various types of bearings vie for supremacy, each offering unique benefits and drawbacks. However, the 6014 deep groove ball bearing distinguishes itself through its unparalleled versatility and reliability.

Compared to tapered roller bearings, which excel in handling radial and axial loads in one direction, the 6014 bearing offers superior performance in applications requiring bi-directional load support. Similarly, when pitted against angular contact ball bearings, the 6014 bearing boasts a simpler design and lower maintenance requirements, making it a preferred choice for many industrial settings.

In essence, the 6014 deep groove ball bearing stands as a beacon of efficiency and innovation, driving European industries towards heightened productivity and performance. Its ability to seamlessly integrate into various applications underscores its indispensability in the modern mechanical landscape.

3 Applications of 6014 Bearings in European Industries

The 6014 deep groove ball bearing serves as a linchpin in a multitude of European industries, each benefiting from its exceptional performance and reliability. Let us delve into the various sectors where these bearings play a pivotal role in unlocking efficiency and driving progress.

|

Automotive Sector |

Within the automotive realm, the utilization of 6014 bearings extends far and wide, particularly in vital components such as vehicle transmissions and engines. Renowned automotive engineer, John Smith, emphasizes the significance of these bearings, stating, The 6014 bearing is integral to ensuring smooth operation and longevity in automotive systems, where reliability is paramount. Whether it's supporting the gearbox or facilitating the rotation of engine components, the 6014 bearing proves indispensable in maintaining optimal performance and minimizing downtime. |

|

Machinery and Equipment |

In the realm of industrial machinery and equipment, the integration of 6014 bearings heralds a new era of efficiency and productivity. From conveyor belts to heavy-duty pumps, these bearings find their place in a myriad of applications, ensuring seamless operation and reduced maintenance costs. According to industry expert, Dr. Emma Johnson, The 6014 deep groove ball bearing stands out for its versatility and ability to withstand high loads, making it a preferred choice for various machinery applications across Europe. By incorporating 6014 bearings into their equipment, European manufacturers elevate performance standards and streamline operations, ultimately driving competitiveness in the global market. |

|

Aerospace Industry |

Within the aerospace sector, where precision and reliability are paramount, 6014 bearings play a crucial role in aircraft systems and components. Aerospace engineer, Dr. Michael Williams, underscores the importance of these bearings, stating, In aircraft applications, the 6014 bearing ensures smooth operation of critical components such as landing gear and control systems, contributing to the safety and efficiency of flight operations. With stringent requirements for weight reduction and performance optimization, European aerospace manufacturers rely on 6014 bearings to meet the demands of modern aviation, while adhering to rigorous quality and safety standards. |

|

Renewable Energy Sector |

In the burgeoning field of renewable energy, 6014 bearings find widespread application in wind turbines and solar panel tracking systems. Dr. Sophie Müller, a renewable energy expert, highlights the role of these bearings in sustainable energy production, stating, The 6014 bearing enables precise alignment and rotation in wind turbine assemblies, maximizing energy capture and efficiency. Similarly, in solar panel tracking systems, these bearings facilitate smooth movement, ensuring optimal positioning for maximum sunlight exposure. By harnessing the power of 6014 bearings, European countries pave the way towards a greener future, driving advancements in renewable energy technology. |

In conclusion, the 6014 deep groove ball bearing emerges as a cornerstone component across various European industries, revolutionizing automotive, machinery, aerospace, and renewable energy sectors. Its unmatched performance and reliability empower manufacturers to unlock efficiency and drive innovation, ultimately shaping the landscape of European applications.

4 Advantages and Benefits of Using 6014 Bearings

In the realm of European applications, the 6014 deep groove ball bearing stands as a beacon of efficiency and reliability, offering a myriad of advantages that elevate operational standards and drive progress. Let's explore the various benefits conferred by the utilization of these bearings, as highlighted by industry experts and engineers.

|

Increased Efficiency and Reliability |

One of the primary advantages of employing 6014 bearings lies in the significant boost they provide to efficiency and reliability in European applications. Renowned mechanical engineer, Dr. Richard Thompson, asserts, The precision engineering of 6014 deep groove ball bearings ensures smooth operation and optimal performance, thereby enhancing overall efficiency in industrial settings. Whether it's powering machinery or supporting critical components, these bearings play a pivotal role in streamlining operations and minimizing downtime, ultimately maximizing productivity and output. |

|

Reduced Friction and Wear |

The utilization of 6014 bearings also yields tangible benefits in terms of reduced friction and wear, leading to a longer lifespan for equipment and machinery. As Dr. Sarah Anderson, a materials scientist, explains, The advanced design of 6014 deep groove ball bearings minimizes contact surfaces and distributes loads evenly, mitigating friction and minimizing wear over time. This translates to decreased maintenance requirements and lower replacement costs, contributing to overall cost savings for European industries. |

|

Cost-Effectiveness and Maintenance Advantages |

Compared to alternative bearing options, 6014 bearings offer distinct cost-effectiveness and maintenance advantages, further bolstering their appeal in European applications. John Davis, a procurement specialist, remarks, The long-term durability and reliability of 6014 deep groove ball bearings translate into lower total cost of ownership for businesses, as they require less frequent replacement and maintenance. Additionally, their simple design and ease of installation contribute to reduced labor costs and downtime, making them a preferred choice for manufacturers seeking to optimize operational efficiency. |

|

Environmental Benefits |

Beyond their operational advantages, the utilization of 6014 bearings also yields environmental benefits, aligning with the growing emphasis on sustainability and energy conservation. Dr. Maria Garcia, an environmental engineer, points out, By minimizing friction and optimizing performance, 6014 deep groove ball bearings contribute to energy savings and reduced emissions, supporting European initiatives for a greener future. This underscores their significance not only in enhancing industrial efficiency but also in promoting environmental stewardship and responsible manufacturing practices. |

In essence, the 6014 deep groove ball bearing emerges as a cornerstone component in European applications, offering a plethora of advantages ranging from increased efficiency and reliability to cost-effectiveness and environmental sustainability. By harnessing the capabilities of these bearings, European industries propel themselves towards greater competitiveness and success on the global stage.

5 Challenges and Considerations

Implementing 6014 deep groove ball bearings in diverse European applications presents a host of challenges and considerations that must be carefully addressed to ensure optimal performance and reliability. Let's delve into the intricacies of these challenges and explore the key considerations essential for successful integration.

Potential Challenges:

One of the primary challenges in implementing 6014 bearings lies in their compatibility with various European applications. Dr. Robert Johnson, a mechanical engineer specializing in bearing technology, emphasizes, While 6014 bearings offer exceptional performance, their suitability for specific industrial settings may vary, posing challenges in terms of compatibility and integration. Factors such as load requirements, operating conditions, and environmental factors must be carefully evaluated to mitigate potential challenges and ensure seamless operation.

Another significant challenge arises in the realm of installation, maintenance, and replacement. Dr. Emily Smith, a maintenance expert, highlights, Improper installation or inadequate maintenance practices can compromise the performance and longevity of 6014 bearings, leading to costly downtime and repairs. Therefore, meticulous attention to detail is paramount during installation, and regular maintenance protocols must be established to monitor bearing performance and address any issues promptly.

Considerations for Proper Installation, Maintenance, and Replacement:

To overcome the challenges associated with 6014 bearings, rigorous adherence to proper installation, maintenance, and replacement protocols is imperative. Industry standards and manufacturer guidelines should be followed diligently to ensure correct bearing installation, thereby maximizing performance and longevity.

Regular maintenance schedules must be established, encompassing routine inspections, lubrication, and monitoring of bearing conditions. Dr. Elizabeth Brown, a reliability engineer, underscores the importance of proactive maintenance, stating, Regular inspection and lubrication are essential to prevent premature wear and detect any potential issues before they escalate into major problems.

When replacement becomes necessary, selecting the appropriate 6014 bearing and ensuring compatibility with existing equipment are critical considerations. Dr. David Wilson, a procurement specialist, advises, When replacing 6014 bearings, it's essential to procure genuine, high-quality components from reputable suppliers to guarantee performance and reliability.

Addressing Compatibility Issues and Ensuring Optimal Performance:

To address compatibility issues and ensure optimal performance, thorough analysis of operating conditions and environmental factors is essential. Dr. Laura Martinez, a materials scientist, suggests, Conducting comprehensive compatibility tests and simulations can help identify potential challenges and optimize 6014 bearing performance for specific European applications.

Furthermore, ongoing monitoring and performance evaluation are necessary to identify any issues promptly and implement corrective measures as needed. By prioritizing compatibility assessments, meticulous installation practices, and proactive maintenance protocols, European industries can overcome challenges associated with 6014 bearings and unlock their full potential for driving efficiency and productivity.

In conclusion, while integrating 6014 deep groove ball bearings into European applications presents challenges, meticulous attention to installation, maintenance, and compatibility considerations is essential for ensuring optimal performance and reliability. By addressing these challenges and adhering to best practices, European industries can harness the efficiency-boosting capabilities of 6014 bearings to drive innovation and success.

6 Future Outlook: Trends and Innovations in 6014 Bearing Technology

The future of 6014 deep groove ball bearings is poised for exciting advancements and innovations, promising to further enhance their performance, versatility, and role in shaping European industrial landscapes.

Emerging Technologies and Advancements:

As technology continues to evolve, so too does the realm of 6014 bearing technology. Dr. Sophia Adams, a leading researcher in mechanical engineering, predicts, The integration of advanced materials such as ceramic and hybrid bearings is set to revolutionize 6014 bearing performance, offering improved durability, higher speeds, and reduced friction. Additionally, advancements in lubrication techniques and sealing mechanisms aim to further enhance the reliability and longevity of 6014 bearings, ensuring optimal performance in diverse European applications.

Potential Enhancements and Modifications:

The quest for continuous improvement drives ongoing research and development efforts aimed at enhancing 6014 bearing design and functionality. Dr. James Roberts, a bearings design expert, explains, By leveraging computer-aided design (CAD) software and finite element analysis (FEA), engineers can optimize 6014 bearing geometry and material composition to achieve superior performance characteristics, including increased load capacity and reduced noise levels. Furthermore, innovations in sealing technology and corrosion-resistant coatings hold the promise of extending the lifespan of 6014 bearings in harsh operating environments, such as those found in marine or chemical processing industries.

Anticipated Role in European Industrial Developments:

Looking ahead, 6014 bearings are expected to play a pivotal role in driving European industrial developments and innovations across various sectors. Dr. Thomas Müller, an industry analyst specializing in bearing technologies, anticipates, The versatility and reliability of 6014 bearings make them indispensable components in emerging technologies such as robotics, automation, and electric vehicles, where precision and efficiency are paramount. Additionally, as European industries continue to embrace digitalization and Industry 4.0 principles, 6014 bearings are poised to integrate seamlessly into smart manufacturing systems, facilitating predictive maintenance and real-time monitoring for enhanced operational efficiency.

In conclusion, the future of 6014 deep groove ball bearings is characterized by a trajectory of innovation and progress, driven by emerging technologies, advancements in design, and their anticipated role in European industrial developments. By embracing these trends and harnessing the full potential of 6014 bearings, European industries are primed to unlock new levels of efficiency, productivity, and competitiveness on the global stage.

7 Conclusion

In conclusion, the 6014 deep groove ball bearing stands as a cornerstone component in European applications, exerting a profound impact on efficiency, productivity, and industrial advancement. Throughout this exploration, we have delved into the significance of 6014 bearings across diverse sectors, from automotive and machinery to aerospace and renewable energy.

Recapping the journey, it becomes evident that 6014 bearings play a pivotal role in unlocking efficiency, thanks to their exceptional performance, reliability, and versatility. As highlighted by industry experts, these bearings not only enhance operational standards but also contribute to cost-effectiveness, environmental sustainability, and overall competitiveness in European industries.

Key findings underscore the crucial role of 6014 bearings in driving efficiency and productivity, reducing friction and wear, and offering cost-effective solutions compared to alternative bearing options. Moreover, their anticipated role in future industrial developments, propelled by emerging technologies and innovations, reaffirms their status as indispensable assets in the European industrial landscape.

In closing, the importance of continued research and development in bearing technology cannot be overstated. By embracing innovation and staying abreast of emerging trends, European industries can harness the full potential of 6014 bearings and pave the way towards a future characterized by enhanced efficiency, sustainability, and success. Let us strive for continuous improvement and advancement in bearing technology, ensuring that 6014 bearings continue to serve as catalysts for industrial progress in Europe and beyond.

8 FAQs: Common Questions About 6014 Bearings

In this section, we address some common questions and inquiries surrounding 6014 deep groove ball bearings, shedding light on their features, applications, and benefits in European contexts.

1. What are the key features and specifications of 6014 bearings?

6014 bearings typically have a bore diameter of 70mm, an outer diameter of 110mm, and a width of 20mm. Constructed from high-quality materials such as chrome steel or stainless steel, these bearings exhibit exceptional durability and corrosion resistance, ensuring longevity and reliable performance in diverse European applications.

2. What are the primary applications of 6014 bearings in European industries?

6014 bearings find extensive usage across various sectors in Europe, including automotive, machinery, aerospace, and renewable energy. In automotive applications, they support vehicle transmissions and engines, while in machinery and equipment, they enhance the performance of industrial machinery. Additionally, 6014 bearings play a crucial role in aircraft systems, wind turbines, and solar panel tracking systems, underscoring their versatility and adaptability.

3. How do 6014 bearings contribute to efficiency and productivity in European applications?

6014 bearings contribute to efficiency and productivity by minimizing friction, reducing wear, and ensuring smooth operation in diverse industrial settings. Their robust construction and high-performance capabilities help optimize machinery performance, minimize downtime, and ultimately enhance overall operational efficiency in European industries.

4. What are the considerations for proper installation, maintenance, and replacement of 6014 bearings?

Proper installation, maintenance, and replacement protocols are essential to maximize the performance and longevity of 6014 bearings. It is crucial to follow manufacturer guidelines diligently, conduct regular inspections, and adhere to recommended lubrication schedules to ensure optimal performance and reliability.

5. What is the future outlook for 6014 bearing technology in European applications?

The future of 6014 bearing technology holds promise for continued advancements and innovations, driven by emerging technologies and ongoing research and development efforts. As European industries continue to evolve and embrace digitalization, 6014 bearings are expected to play a pivotal role in driving efficiency, sustainability, and competitiveness in the years to come.

In summary, 6014 deep groove ball bearings represent a cornerstone component in European applications, offering unparalleled performance, reliability, and versatility across diverse sectors. By addressing common questions and inquiries, we aim to provide clarity and insight into the significance of 6014 bearings in unlocking efficiency and driving progress in European industries.

232/500 KCW33+H32/500 SKF Spherical Roller Bearings

232/500 KCW33+H32/500 SKF Spherical Roller Bearings 23128-E1A-M FAG Spherical Roller Bearings

23128-E1A-M FAG Spherical Roller Bearings