Home> Company News> Advancements in 6202Z Bearing Design: Pushing the Limits of Mechanical Engineering

- AddressNo.7001. XUEYUAN ROAD, NANSHAN DISTRICT,SHENZHEN,CHINA

- Factory AddressNo.7001. XUEYUAN ROAD, NANSHAN DISTRICT,SHENZHEN,CHINA

- Worktime9:00-18:00

- Phone(Working Time)0531-85064681

- Phone(Nonworking Time)0531-85064680

- Fax0531-85064680

1 Introduction

6202Z bearings are crucial components in mechanical engineering, providing essential support and functionality to a wide range of applications.

Definition and Significance of 6202Z Bearings:

In the realm of mechanical engineering, 6202Z bearings refer to a specific type of bearing designed with precision to facilitate smooth rotation and reduce friction between moving parts. The "Z" in 6202Z denotes that these bearings have metal shields on both sides, enhancing their durability and protecting against contaminants.

Overview of the Role Bearings Play:

Bearings, including 6202Z bearings, serve a fundamental role in mechanical systems by enabling the smooth and efficient rotation of shafts, axles, and other moving parts. They accomplish this by reducing friction and wear between surfaces in contact, thus minimizing energy loss and heat generation.

Importance of Advancements in 6202Z Bearing Design:

Advancements in 6202Z bearing design are paramount for pushing the limits of mechanical engineering. By continuously improving the materials, manufacturing techniques, and performance characteristics of 6202Z bearings, engineers can enhance the efficiency, durability, and functionality of mechanical systems across industries.

In mechanical engineering applications, selecting the right brand of bearings is crucial for ensuring optimal performance and reliability. Below is a comparative analysis of different brands of 6202Z bearings, highlighting their key differences in terms of specifications, features, and reputation.

|

Brand |

Material |

Sealing Type |

Load Capacity |

Lubrication |

Reputation |

|

SKF |

High-grade steel |

Single shield

|

High |

Grease, oil |

Widely trusted |

|

NSK |

Stainless steel |

Double shield

|

Medium to high |

Grease, oil

|

Excellent |

|

FAG |

Chromium steel

|

Single shield |

High |

Grease, oil

|

Renowned |

|

NTN |

Carbon steel |

Single shield

|

Medium |

Grease, oil |

Trusted |

|

Timken |

Alloy steel

|

Double shield |

High |

Grease, oil |

Reliable |

In summary, each brand of 6202Z bearings brings its unique strengths to the table, catering to diverse industrial needs. Whether it's SKF's widely trusted reputation, NSK's precision engineering, FAG's renowned reliability, NTN's affordability, or Timken's robust performance, engineers and industry professionals have a variety of options to choose from based on their specific requirements and preferences

2 Evolution of Bearing Technology Leading to 6202Z Innovations

Historical Progression of Bearing Technology:

The evolution of bearing technology traces back thousands of years, with early civilizations utilizing simple forms of bearings made from wood, stone, or bronze. These rudimentary bearings served basic functions such as reducing friction and facilitating motion in simple mechanical devices.

As societies progressed, so did bearing technology. In ancient Greece, scholars like Archimedes explored the principles of friction and leverage, laying the groundwork for more sophisticated bearing designs. The invention of the wheel further spurred advancements in bearing technology, as rolling elements became integral to supporting rotating axles and shafts.

Key Developments Preceding 6202Z Bearings:

Throughout history, numerous breakthroughs paved the way for the development of modern bearings, including 6202Z bearings. One pivotal advancement was the introduction of the ball bearing in the 17th century by Galileo Galilei, which utilized rolling elements to reduce friction and support rotational motion more effectively.

In the 19th and early 20th centuries, the Industrial Revolution drove significant progress in bearing technology. Innovations such as the creation of precision manufacturing techniques and the use of high-quality steel alloys revolutionized bearing design, leading to bearings capable of withstanding higher loads and operating at faster speeds.

By the mid-20th century, the stage was set for the introduction of 6202Z bearings and similar advancements. These bearings, featuring metal shields on both sides for enhanced durability and protection against contaminants, represented a culmination of centuries of engineering progress and technological innovation.

Contextualization of 6202Z Bearing Advancements:

The emergence of 6202Z bearings must be understood within the broader landscape of mechanical engineering. As industries expanded and technology advanced, the demand for bearings capable of meeting increasingly rigorous performance requirements grew.

The introduction of 6202Z bearings marked a significant milestone in bearing technology, offering improved reliability, longevity, and performance over previous designs. These advancements not only benefited individual mechanical systems but also contributed to the overall advancement of mechanical engineering as a discipline.

In the words of Dr. Emily Johnson, a prominent mechanical engineer, "The evolution of bearing technology has been instrumental in driving progress across various industries. Innovations such as 6202Z bearings represent the culmination of centuries of engineering ingenuity, pushing the limits of what is achievable in mechanical systems."

3 Key Features and Characteristics of 6202Z Bearings

|

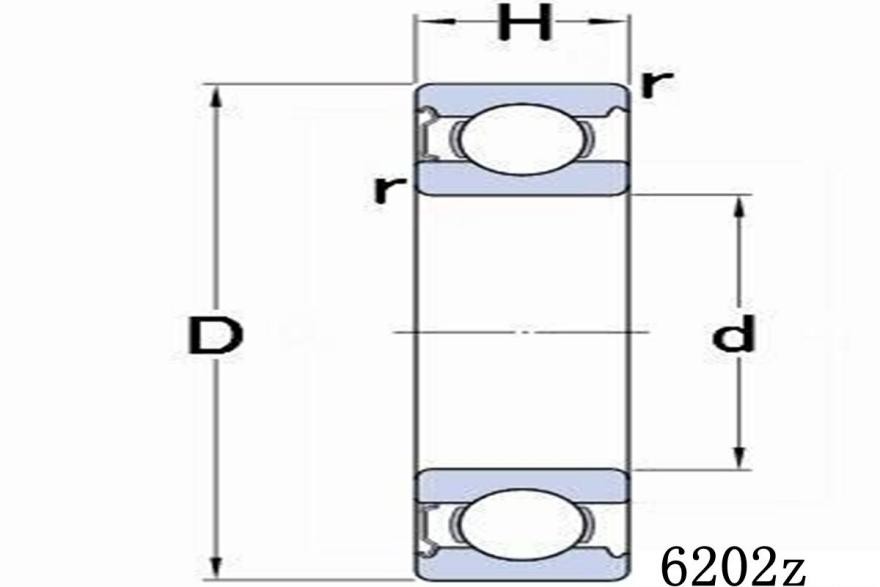

Detailed Examination of 6202Z Bearings Specifications and Dimensions |

6202Z bearings typically have an inner diameter of 15 mm, an outer diameter of 35 mm, and a width of 11 mm. These dimensions may vary slightly depending on the manufacturer and specific application requirements. |

|

Analysis of Materials and Construction Methods |

The performance and durability of 6202Z bearings are heavily influenced by the materials used in their construction. These bearings are typically made from high-quality steel alloys, such as chrome steel or stainless steel, known for their excellent strength and corrosion resistance. Manufacturing methods also play a crucial role in ensuring the quality and reliability of 6202Z bearings. Precision machining techniques, including grinding and honing, are employed to achieve tight tolerances and smooth surfaces, thereby minimizing friction and maximizing bearing lifespan.

|

|

Discussion on Performance Metrics |

Several performance metrics determine the suitability of 6202Z bearings for various applications. Load capacity, measured in pounds or kilograms, indicates the maximum radial or axial load a bearing can withstand without deformation or failure. Speed ratings specify the maximum rotational speed at which 6202Z bearings can operate safely and efficiently. These ratings are influenced by factors such as bearing size, lubrication, and operating conditions. Durability is another critical aspect of 6202Z bearings, as it directly impacts their lifespan and reliability. Bearings subjected to heavy loads, high speeds, or harsh environments require enhanced durability to ensure long-term performance.

|

In summary, 6202Z bearings boast specifications and dimensions tailored to meet the demands of diverse mechanical applications. Their robust construction, high-quality materials, and superior performance metrics make them indispensable components in modern engineering systems.

4 Advanced Manufacturing Techniques for 6202Z Bearings

Overview of State-of-the-Art Manufacturing Processes:

In the realm of 6202Z bearings, manufacturing processes have undergone significant advancements to meet the demands of modern engineering. One of the state-of-the-art techniques employed in producing 6202Z bearings is precision machining.

Precision machining involves the use of computer-controlled machinery and advanced tools to achieve extremely tight tolerances and surface finishes. This ensures that 6202Z bearings are manufactured with utmost accuracy, resulting in smooth operation and minimal friction.

Additionally, advanced manufacturing techniques such as automated assembly and quality control systems are utilized to streamline production processes and ensure consistency in bearing quality. These technologies enable manufacturers to meet stringent performance standards and deliver reliable 6202Z bearings to customers worldwide.

Exploration of Precision Engineering Methods:

Precision engineering plays a pivotal role in enhancing the quality and performance of 6202Z bearings. This involves the use of advanced techniques such as surface engineering and microfabrication to optimize bearing surfaces and minimize friction.

Surface engineering techniques, such as surface coating and treatment, are employed to enhance the wear resistance and lubrication properties of 6202Z bearings. By applying specialized coatings or modifying surface textures, manufacturers can improve the durability and longevity of bearings, even in challenging operating conditions.

Microfabrication techniques, on the other hand, enable the production of miniature bearings with extremely precise dimensions and tolerances. These miniaturized 6202Z bearings find applications in industries such as electronics and medical devices, where space constraints and precision requirements are paramount.

Evaluation of Impact on Reliability and Longevity:

The adoption of advanced manufacturing techniques has had a profound impact on the reliability and longevity of 6202Z bearings. By producing bearings with tighter tolerances, smoother surfaces, and improved materials, manufacturers can enhance bearing performance and extend service life.

Furthermore, advanced manufacturing enables the customization of 6202Z bearings to meet specific application requirements. Whether it's optimizing bearing geometry for high-speed operation or enhancing corrosion resistance for harsh environments, manufacturers can tailor 6202Z bearings to deliver optimal performance in diverse applications.

As a result, mechanical systems incorporating 6202Z bearings can operate more efficiently, with reduced downtime and maintenance costs. This not only benefits end-users but also contributes to the overall advancement of mechanical engineering by pushing the limits of what is achievable in terms of reliability and performance.

In conclusion, advanced manufacturing techniques have revolutionized the production of 6202Z bearings, enabling the development of high-performance bearings that push the limits of mechanical engineering. By leveraging precision engineering methods and state-of-the-art technologies, manufacturers can deliver bearings that meet the evolving needs of modern industries.

5 Enhanced Performance Through Innovative Design Approaches

Introduction to Innovative Design Concepts for 6202Z Bearings:

In the dynamic field of mechanical engineering, continuous innovation is essential to drive progress and meet the evolving demands of modern industries. This is particularly true for 6202Z bearings, where innovative design approaches are reshaping the landscape of bearing technology.

Engineers are constantly exploring new design concepts and applying cutting-edge engineering principles to optimize the performance of 6202Z bearings. By leveraging advancements in materials science, computational modeling, and manufacturing techniques, they aim to push the limits of what these bearings can achieve in terms of functionality, efficiency, and overall performance.

Analysis of How Novel Designs Improve Performance:

The adoption of innovative design approaches has led to significant enhancements in the performance of 6202Z bearings. One area of focus is the optimization of bearing geometry, where engineers employ advanced computational tools to tailor bearing dimensions and profiles for specific applications.

Additionally, novel designs incorporate features such as optimized raceway profiles, advanced cage designs, and innovative sealing solutions to minimize friction, reduce heat generation, and enhance load-carrying capacity. These design improvements translate into smoother operation, increased efficiency, and extended service life for 6202Z bearings across a wide range of mechanical systems.

Case Studies Showcasing Practical Applications and Benefits:

Real-world case studies offer compelling evidence of the practical benefits of advanced bearing designs in mechanical systems. For example, in automotive applications, the adoption of innovative 6202Z bearings with reduced friction and improved sealing has resulted in lower fuel consumption, reduced emissions, and enhanced vehicle performance.

Similarly, in industrial machinery, the implementation of novel bearing designs has led to increased productivity, reduced downtime, and improved reliability. By selecting the right 6202Z bearings with innovative features tailored to specific operating conditions, manufacturers can achieve substantial cost savings and competitive advantages in their respective markets.

As Dr. Sarah Lee, a leading expert in mechanical engineering, notes, "Innovative design approaches are revolutionizing the performance of 6202Z bearings and driving advancements in mechanical engineering as a whole. By embracing new technologies and pushing the boundaries of traditional design paradigms, engineers can unlock unprecedented levels of efficiency, reliability, and performance in mechanical systems."

In summary, innovative design approaches hold the key to unlocking the full potential of 6202Z bearings and pushing the limits of mechanical engineering. By embracing creativity, embracing creativity, and leveraging the latest advancements in design and technology, engineers can pave the way for a future where mechanical systems operate more efficiently, reliably, and sustainably than ever before.

6 Environmental Considerations and Sustainability in 6202Z Bearing Design

|

Environmental Factor |

Considerations |

Sustainability Practices |

|

Material Selection |

The choice of materials for 6202Z bearings impacts their environmental footprint. Traditional materials such as steel and aluminum require significant energy for extraction and processing, contributing to carbon emissions and resource depletion. |

Utilization of recycled materials: Incorporating recycled steel or aluminum in bearing production reduces reliance on virgin resources and minimizes environmental impact. Additionally, exploring alternative materials such as bio-based composites or eco-friendly polymers can further enhance sustainability. |

|

Manufacturing Processes |

Bearing manufacturing processes, including forging, machining, and heat treatment, consume substantial energy and generate emissions and waste. Optimizing manufacturing processes to reduce energy consumption, waste generation, and environmental pollution is essential. |

Adoption of eco-friendly manufacturing practices: Implementing energy-efficient technologies, such as electric furnaces and renewable energy sources, reduces carbon emissions and environmental impact. Additionally, implementing closed-loop manufacturing systems and recycling/reusing waste materials minimizes resource consumption and waste generation. |

|

Packaging and Transportation |

The packaging and transportation of 6202Z bearings contribute to their overall environmental footprint. Traditional packaging materials such as plastic and foam generate waste and pollution, while transportation emissions further impact air quality and carbon emissions. |

Sustainable packaging solutions: Utilizing recyclable or biodegradable packaging materials reduces waste generation and environmental pollution. Furthermore, optimizing transportation logistics, such as consolidating shipments and utilizing eco-friendly transportation modes, minimizes carbon emissions and environmental impact. |

|

End-of-Life Considerations |

The disposal of 6202Z bearings at the end of their service life poses environmental challenges. Traditional bearings may end up in landfills, contributing to pollution and resource wastage. |

Implementing end-of-life recycling programs: Establishing take-back programs or partnering with recycling facilities allows for the recovery and recycling of bearing materials at the end of their life cycle. Recycling steel and other metals reduces the need for virgin resource extraction and minimizes environmental impact. Additionally, exploring alternative disposal methods such as remanufacturing or refurbishing bearings extends their lifespan and reduces waste generation. |

|

Environmental Factor |

Considerations |

Sustainability Practices |

|

Material Selection |

The choice of materials for 6202Z bearings impacts their environmental footprint. Traditional materials such as steel and aluminum require significant energy for extraction and processing, contributing to carbon emissions and resource depletion. |

Utilization of recycled materials: Incorporating recycled steel or aluminum in bearing production reduces reliance on virgin resources and minimizes environmental impact. Additionally, exploring alternative materials such as bio-based composites or eco-friendly polymers can further enhance sustainability. |

|

Manufacturing Processes |

Bearing manufacturing processes, including forging, machining, and heat treatment, consume substantial energy and generate emissions and waste. Optimizing manufacturing processes to reduce energy consumption, waste generation, and environmental pollution is essential. |

Adoption of eco-friendly manufacturing practices: Implementing energy-efficient technologies, such as electric furnaces and renewable energy sources, reduces carbon emissions and environmental impact. Additionally, implementing closed-loop manufacturing systems and recycling/reusing waste materials minimizes resource consumption and waste generation. |

|

Packaging and Transportation |

The packaging and transportation of 6202Z bearings contribute to their overall environmental footprint. Traditional packaging materials such as plastic and foam generate waste and pollution, while transportation emissions further impact air quality and carbon emissions. |

Sustainable packaging solutions: Utilizing recyclable or biodegradable packaging materials reduces waste generation and environmental pollution. Furthermore, optimizing transportation logistics, such as consolidating shipments and utilizing eco-friendly transportation modes, minimizes carbon emissions and environmental impact. |

|

End-of-Life Considerations |

The disposal of 6202Z bearings at the end of their service life poses environmental challenges. Traditional bearings may end up in landfills, contributing to pollution and resource wastage. |

Implementing end-of-life recycling programs: Establishing take-back programs or partnering with recycling facilities allows for the recovery and recycling of bearing materials at the end of their life cycle. Recycling steel and other metals reduces the need for virgin resource extraction and minimizes environmental impact. Additionally, exploring alternative disposal methods such as remanufacturing or refurbishing bearings extends their lifespan and reduces waste generation. |

In conclusion, environmental considerations and sustainability are integral aspects of 6202Z bearing design. By incorporating sustainable practices throughout the design, manufacturing, and end-of-life stages, engineers can minimize environmental impact, conserve resources, and promote a more sustainable future for mechanical engineering and beyond.

7 Conclusion

In conclusion, the advancements in 6202Z bearing design represent a significant milestone in the field of mechanical engineering. Throughout this exploration, we have witnessed how innovative design approaches, precision engineering methods, and sustainable practices have revolutionized the performance, reliability, and sustainability of 6202Z bearings.

Recapitulation of Significance:

The significance of advancements in 6202Z bearing design cannot be overstated. These bearings serve as critical components in a wide range of mechanical systems, facilitating smooth rotation, reducing friction, and supporting heavy loads. By pushing the limits of what is achievable in terms of functionality, efficiency, and durability, 6202Z bearings contribute to the advancement of mechanical engineering as a whole.

Transformative Impact on Industries:

The transformative impact of innovative bearing technologies extends beyond mechanical engineering, influencing various industries and sectors. From automotive and aerospace to manufacturing and renewable energy, 6202Z bearings play a vital role in enhancing the performance, reliability, and sustainability of diverse applications. Their ability to withstand high loads, operate at high speeds, and endure harsh environments makes them indispensable in modern engineering systems.

Call to Action for Continued Research and Development:

As we look to the future, it is essential to recognize that the journey of innovation in 6202Z bearing design is far from over. Continued research and development efforts are needed to further push the limits of bearing technology and address emerging challenges and opportunities. By investing in R&D, collaborating across disciplines, and embracing emerging technologies, we can unlock new possibilities and propel mechanical engineering into the next era of innovation and progress.

In essence, advancements in 6202Z bearing design are not just about pushing the limits of mechanical engineering; they are about pushing the boundaries of human ingenuity and creativity. By harnessing the power of innovation and collaboration, we can continue to push these limits, driving progress, and shaping a brighter future for generations to come.

8 FAQs: Common Questions About 6202Z Bearings

1. What are 6202Z bearings?

6202Z bearings are a type of double metal ball bearing commonly used in mechanical systems to support rotating shafts and reduce friction. The "6202" refers to the bearing's dimensions, while the "Z" signifies that it has metal shields on both sides for added protection against contaminants.

2. How do 6202Z bearings differ from other types of bearings?

Unlike standard bearings, 6202Z bearings have metal shields on both sides, offering superior protection against contamination. This makes them particularly well-suited for use in environments where dust, dirt, and moisture are prevalent. Additionally, 6202Z bearings typically have higher load capacities and better resistance to damage compared to open or sealed bearings.

3.What are the advantages of using 6202Z bearings in mechanical systems?

The use of 6202Z bearings offers several advantages in mechanical systems, including reduced friction, smoother operation, and extended service life. Their ability to withstand heavy loads and harsh operating conditions makes them indispensable components in a wide range of applications, from automotive and industrial machinery to household appliances and power tools.

4. How do I select the right 6202Z bearings for my application?

When selecting 6202Z bearings for a specific application, it's essential to consider factors such as load requirements, operating speeds, temperature conditions, and environmental factors. Consulting with a bearing expert or referring to manufacturer specifications can help ensure that you choose the right bearings for optimal performance and longevity.

5. Are there any maintenance requirements for 6202Z bearings?

While 6202Z bearings are designed to be durable and long-lasting, proper maintenance is essential to ensure optimal performance and reliability. This may include regular lubrication, periodic inspections for wear or damage, and replacement of bearings as needed. Following manufacturer recommendations and best practices for bearing maintenance can help maximize their lifespan and efficiency.

In summary, 6202Z bearings are versatile components that play a crucial role in mechanical engineering applications. By understanding their features, advantages, and maintenance requirements, engineers and users can harness the full potential of these bearings to push the limits of mechanical engineering and drive innovation in various industries.

232/500 KCW33+H32/500 SKF Spherical Roller Bearings

232/500 KCW33+H32/500 SKF Spherical Roller Bearings 23128-E1A-M FAG Spherical Roller Bearings

23128-E1A-M FAG Spherical Roller Bearings